1. Муқаддима

This manual provides detailed instructions for the setup, operation, and maintenance of your ELEGOO Saturn 4 Ultra 16K Resin 3D Printer. Designed for high-speed and precision printing, this MSLA printer features a 16K mono LCD, smart resin tank heating, an AI camera, and built-in Wi-Fi for an enhanced 3D printing experience. Please read this manual thoroughly before using the printer to ensure optimal performance and safety.

Image 1.1: The ELEGOO Saturn 4 Ultra 16K Resin 3D Printer.

2. Рӯйхати бастабандӣ

Пеш аз оғози насб, боварӣ ҳосил кунед, ки ҳамаи компонентҳо дар баста мавҷуданд.

Image 2.1: Included items in the ELEGOO Saturn 4 Ultra 16K package.

- Принтери Saturn 4 Ultra 16K 3D

- Сохтани судї

- Зарфи қатрон

- Ҳунар

- Табақи қатрон

- Диски флеши USB

- Дастпӯшакҳо

- Маска

- Виддаҳои эҳтиётӣ

- Скрепер

- Адаптер

- Маҷмӯаи асбобҳо

- Дастури корбар (ин ҳуҷҷат)

3. Дастурамал оид ба насб

The ELEGOO Saturn 4 Ultra 16K is designed for ease of use, featuring automatic leveling to simplify the initial setup process.

- Кушодани: Принтер ва ҳамаи лавозимотро аз бастабандӣ бодиққат хориҷ кунед.

- Ҷойгиршавӣ: Place the printer on a stable, level surface in a well-ventilated area, away from direct sunlight and dust.

- Пайвасти барқ: Connect the power adapter to the printer and a suitable power outlet.

- Насби плитаи сохтмонӣ: Install the build plate onto the Z-axis arm. The printer features a quick-release mechanism for easy attachment and removal.

- Resin Tank Placement: Place the resin tank securely into its designated slot on the printer.

- Сатҳи автоматӣ: The printer is equipped with an intelligent mechanical sensor for automatic leveling. Follow the on-screen prompts to initiate the auto-leveling process. If necessary, auxiliary manual leveling can be performed to achieve optimal results.

Image 3.1: The automatic leveling system ensures the printer is ready for use.

4. Дастурҳои истифодабарӣ

4.1 Resin Tank Heating

The ELEGOO Saturn 4 Ultra 16K features an intelligent resin tank heating system. A built-in temperature sensor monitors the resin temperature in real-time, and the heating device can preheat the resin for up to 24 hours, reaching a temperature of 30°C. Maintaining the optimal resin temperature is crucial for improving print success rates, especially in cooler environments.

Image 4.1: The intelligent resin tank heating system.

4.2 High-Speed Printing with Tilt-Release Technology

This printer utilizes revolutionary tilt-release technology to achieve high printing speeds of up to 150mm/h. By tilting the resin tank up and down, the printed model is separated from the film, reducing suction and minimizing Z-axis movement time. This innovation significantly accelerates the printing process.

Image 4.2: Illustration of high-speed printing with tilt-release technology.

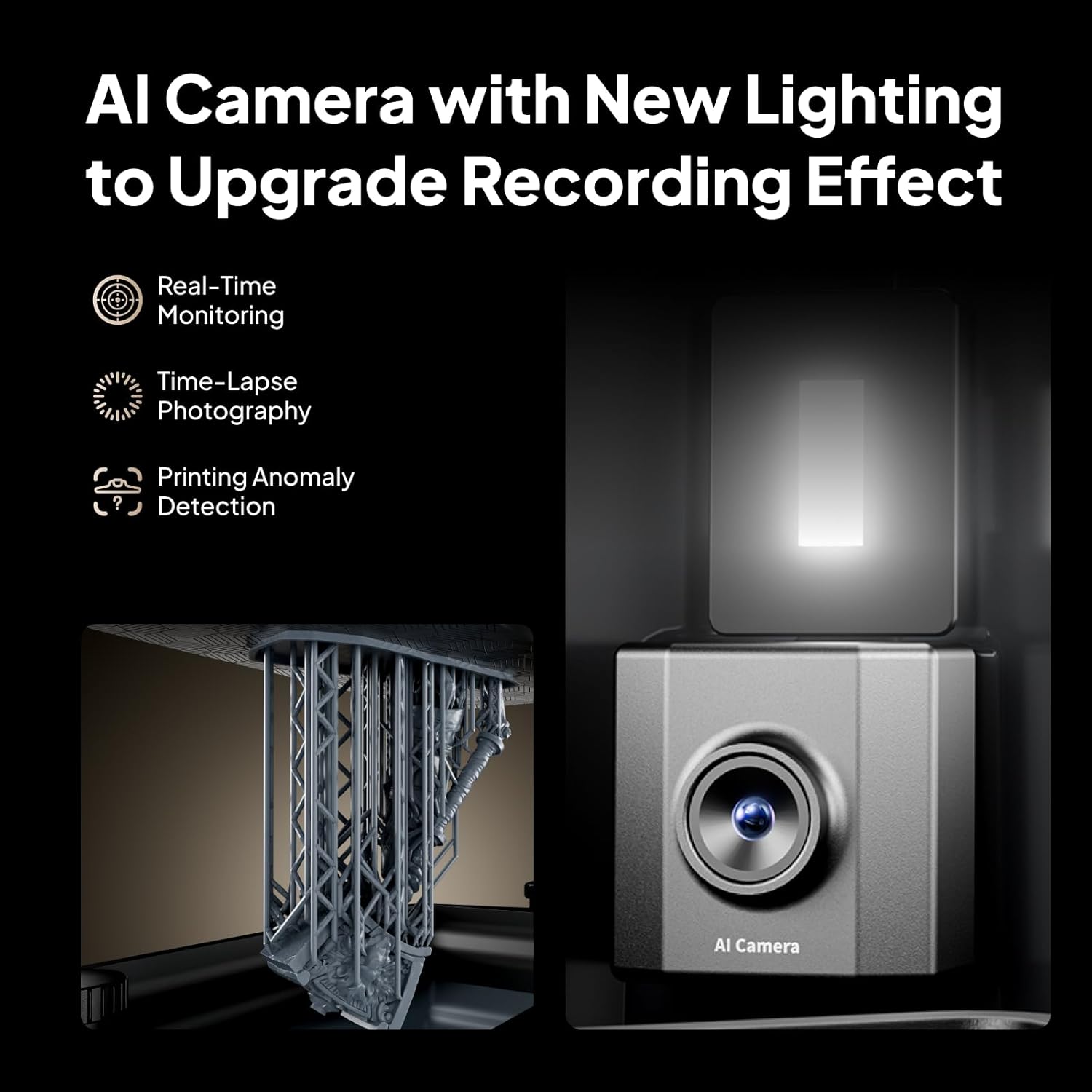

4.3 AI Camera and Lighting for Monitoring

The integrated AI camera allows for real-time monitoring of the printing process. It intelligently detects common issues such as an empty build plate or model warping, enabling prompt intervention. Additional high-brightness lighting ensures clear visibility and recording of the print, supporting time-lapse photography.

Image 4.3: The AI camera and lighting system for print monitoring.

4.4 Intelligent Mechanical Sensors

Beyond automatic leveling, the intelligent mechanical sensors detect various printing anomalies, including insufficient resin, the presence of foreign objects, or excessively high lamp panel temperatures. In the event of a power failure during printing, the system is designed to resume the printing process once power is restored, minimizing material waste.

Image 4.4: The intelligent system's anomaly detection and power-loss recovery features.

4.5 Wi-Fi Cluster Printing and Firmware Updates

The printer supports Wi-Fi connectivity (2.4G and 5G networks) for file transfer at speeds of 6-10 Mbps, eliminating the need for a USB flash drive. Within the same local area network, multiple printers can be controlled simultaneously for cluster printing. Remote control and data transmission are secure, fast, and stable. Firmware updates can be conveniently performed via OTA (Over-The-Air).

Image 4.5: The Wi-Fi cluster printing capability.

4.6 Large Print Size

The ELEGOO Saturn 4 Ultra 16K offers a generous print volume of 211.68mm (L) × 118.37mm (W) × 220mm (H), allowing for the creation of larger models or multiple smaller prints in a single batch.

Image 4.6: Print volume dimensions of the Saturn 4 Ultra 16K.

5. Нигоҳдорӣ

Нигоҳдории мунтазам умри дароз ва кори пайвастаи чопгари 3D-и шуморо таъмин мекунад.

- Cleaning the Resin Tank: After each print, carefully pour any remaining resin back into its bottle using a funnel. Clean the resin tank with isopropyl alcohol (IPA) and a soft cloth. The resin tank features a double port for easy pouring.

- Тозакунии плитаҳои сохтмонӣ: Clean the build plate with IPA after removing printed models. The quick-release build plate design facilitates easy removal and cleaning.

- Resin Management: Always handle resin in a well-ventilated area and wear appropriate personal protective equipment (gloves, mask). Store resin in its original container, away from direct sunlight.

- FEP Film Inspection: Regularly inspect the FEP film in the resin tank for any damage or cloudiness. Replace if necessary to prevent print failures. The replaceable tank lock design aids in maintenance.

- Printer Exterior: Keep the printer's exterior clean and free of dust and resin spills.

Image 5.1: Design features that simplify maintenance, such as the quick-release build plate and resin pouring ports.

6. Баррасии мушкилот

This section addresses common issues you might encounter and provides solutions. The ELEGOO Saturn 4 Ultra 16K's intelligent systems are designed to detect many anomalies, but manual checks may still be required.

- Print Failure (Model not sticking to build plate):

- Боварӣ ҳосил кунед, ки лавҳаи сохтмон тоза ва дуруст ҳамвор карда шудааст.

- Verify the resin tank's FEP film is clean and undamaged.

- Check resin temperature; ensure the smart tank heater is active and maintaining 30°C.

- Adjust bottom exposure time in your slicer software.

- Print Failure (Partial or Incomplete Prints):

- Check resin level in the tank; the intelligent sensor may alert you to insufficient resin.

- Inspect the FEP film for damage or cured resin particles.

- Ensure the print file вайрон нашудааст.

- Тасдиқ кунед лamp panel temperature is within operating limits (intelligent sensor detects high temperatures).

- Принтер ҷавоб намедиҳад:

- Пайвастагии барқро тафтиш кунед.

- Чопгарро аз нав оғоз кунед.

- Ensure firmware is up to date via OTA update.

- Масъалаҳои пайвасти Wi-Fi:

- Ensure the printer is within range of your 2.4G or 5G Wi-Fi network.

- Verify Wi-Fi credentials are correctly entered.

- Роутер ва принтери худро аз нав оғоз кунед.

7. Мушаххасоти

| Хусусият | Тафсилот |

|---|---|

| Бренд | ELEGOO |

| Рақами модел | ELEGOO SATURN 4 ULTRA 16K |

| Андозаҳои маҳсулот | 25.9 x 17.3 x 16.1 инч (65.8 x 43.9 x 40.9 см) |

| Вазни ашё | 41.2 фунт (18.7 кг) |

| Материал | Металл |

| Ранги | Saturn 4 Ultra 16K |

| Дастгир карда шудааст File Формат | STL |

| Суръати максималии чоп | Up to 150mm/h |

| Resin Tank Heating | Smart heating, up to 30°C |

| Пайвастшавӣ | Built-in Wi-Fi (2.4G and 5G) |

| Хусусиятҳои AI | AI Camera with Light, Anomaly Detection |

8. Кафолат ва дастгирӣ

For detailed warranty information, please refer to the warranty card included with your product or visit the official ELEGOO webсайт.

Should you encounter any issues or require technical assistance, please contact ELEGOO customer support. You can find contact information on the official ELEGOO webсайт ё тавассути платформаи хариди худ.